Cabot Creamery Cooperative

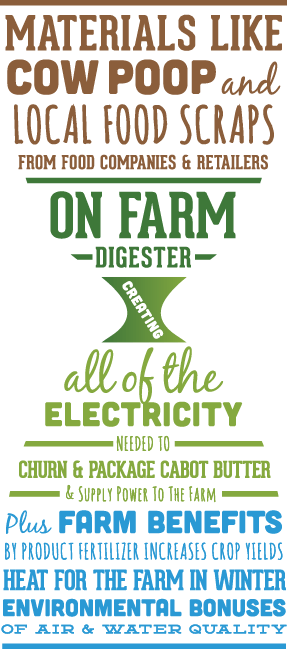

Cow Poop & Food Scraps…Organic Materials In, Electricity Out

Barstow’s Longview Farm has a herd of 450 animals. 250 are milking cows and the remaining are young replacement stock and steers. The barn housing the milk cows has pipes hooked up to the anaerobic digester. This manure, with the help of gravity and pumps, is funneled underground and into the digester every hour.

Barstow’s Longview Farm has a herd of 450 animals. 250 are milking cows and the remaining are young replacement stock and steers. The barn housing the milk cows has pipes hooked up to the anaerobic digester. This manure, with the help of gravity and pumps, is funneled underground and into the digester every hour.

After the digester has captured and converted the gas to power, the cow manure and organic feedstock is far less smelly but is still nutrient rich. The liquid byproduct of digestion is piped underground to the blue slurry storage tanks. The Barstow’s will fertilize their 400 acres of farmland with this fertilizer.

Vanguard Renewables has contracted with recycling company Casella Organics, Inc. to supply organic feedstock to the farm and RCM for the digester design. Manufacturing byproducts from companies become recycled feedstocks for the digester. Real Farm Power meets both Cabot’s key retailers and state government goals for organic diversion from landfills. The management of the nutrients on the farm meets or exceeds the standards set by the NRCS (Natural Resources Conservation Service) of the United States Department of Agriculture.

Organic feedstocks arrive at the farm in liquid form and are piped from the delivery tanker to the underground storage tanks. The tank’s heat is maintained by the hot water from the digester, keeping it a closed loop system. Every hour, the feedstock is added into the digester and mixed with the manure.

Barstow’s Longview Farm receives organic material from 15 different food companies including their cooperative Agri-Mark, Inc., as well as Cains Foods, Inc., and HP Hood. They also receive food that would otherwise go to landfill from local food retailer Geissler’s Supermarket.